Vinylethylbenzene hasn’t always carried the attention it holds today. When the mid-twentieth century boom in organic synthesis began, petrochemical companies scrambled to create newer intermediates for resins, plastics, and specialty chemicals. Vinylbenzene’s story, wrapped within the broader expansion of aromatic vinyl compounds, became more interesting after manufacturers learned to separate its isomers efficiently. People working in chemical plants at that time talked about the improvements in distillation columns and fractionators, allowing these structures to come out crisp rather than tangled in a blend. The old research archives show that, for years, the compound spent more time as a curious mixture than a well-defined intermediate. The shift from broad, impure cuts to reliable production mirrored the move toward product accountability and higher standards across the industry.

The chemical world knows vinylethylbenzene mainly as a colorless liquid, often sourced in bulk from ethylbenzene through processes that juggle both efficiency and selectivity. Most users today are either in the plastics, resin, or adhesive sectors, where this molecule’s role as a monomer or intermediate shapes how polymers cure, crosslink, and combine. Chemists walking the factory floor talk about how changing the ratio of para- to meta-isomers tweaks polymer behaviors, bringing direct influence over final product toughness or polish. This granular control places vinylethylbenzene high in discussions about process optimization—especially where industrial coatings and ion exchange resins need unique mixtures.

Vinylethylbenzene catches the eye because of its moderate boiling range—roughly 193-199°C for the mix of isomers—and its pleasant, though faint, aromatic smell. The liquid flows easily, with a density hovering near 0.9 g/cm³, and it resists dissolving in water but jumps into organic solvents without hassle. Those in synthesis circles like its stability at standard temperatures, but they keep a watchful eye on its reactivity around strong oxidizers or acids. Its molecular structure grants the kind of double bond chemists love for modifications. The molecule’s backbone lets it slide into free-radical polymerization, forming tough, consistent chains when given just the right nudge from peroxides or ultraviolet light.

Industrial supply houses carry vinylethylbenzene under many different specification sheets, yet the best ones shoot for high purity—above 98%, sometimes peaking near 99.5%. Specifications pin down limits for moisture, peroxide levels, and non-volatile residues, since even small deviations impact how well polymers set or how resins behave. Every drum has labels reflecting standardized guidelines: UN numbers for transport, clear warnings for skin and inhalation risks, and storage advice that says, loud and clear, to keep away from sparks. Safety data sheets back up this labeling with numbers for flash point (down near 65°C) and advice for personal protective equipment, which workers treat as mandatory, not optional.

Most vinylethylbenzene today gets made by alkylating styrene with ethylene in the presence of acid catalysts like aluminum chloride. Old-timers remember the messy early attempts that needed constant cleanup, as product streams filled with more isomers than anyone liked. Process engineers worked out better separation and washing tricks over time, squeezing out purer product and dropping waste. Many plants also recover the compound as a byproduct during ethylbenzene production, making the economics better for integrated facilities. Anyone with a distillation background recognizes the challenge in cutting vinylethylbenzene clean from similar-boiling lateral products.

Vinylethylbenzene jumps into addition reactions quickly where its double bond sits. In polymer chemistry, that characteristic lets it participate in crosslinking, especially for producing high-impact polystyrenes or specialty resin systems. Once in the reactor, it picks up initiators—think benzoyl peroxide or AIBN—and opens up possibilities for block copolymers or functional materials. At the same time, its aromatic ring stays open for electrophilic substitution, which means chemists can tack on further groups in post-reaction modification when special performance is needed. Over the years, labs tinkering with polymer modifications have learned that even tiny variances in reaction temperature, catalyst loading, or isomer ratio change outcome properties dramatically.

Supply catalogs and technical bulletins usually place vinylethylbenzene alongside other names: 1-phenylpropene, 1-ethenyl-4-ethylbenzene, and the catch-all term “VEB.” International chemical inventories sometimes list commercial blends by meta/para ratios, with older trade names from companies no longer in the game. Certain resin blends highlight the “divinylbenzene-ethylvinylbenzene” mix, showing just how tightly this chemical links with other vinyl aromatics in day-to-day production. For researchers digging through older journals or patent archives, recognizing all those alternates spares a lot of confusion.

Every operator handling this material follows rigorous safety steps. Flammable vapor, skin irritant, and hazardous to aquatic life—vinylethylbenzene wears its hazard classification plainly. In real shops, this means proper gloves and goggles, high-quality ventilation, and intake monitoring that alarms at the faintest odor out of range. Spills are rare, but protocols keep absorbents and cleanup gear right at hand. Long storage calls for nitrogen blanketing and temperature controls, as long exposure to sunlight or heat makes peroxides creep up, a point no plant manager takes lightly. Federal and international regulations draw a firm line on emissions, so modern shops use closed-loop transfer and secondary containment, and they make sure all waste streams feed to approved incineration or recovery.

Look across the plastics industry and vinylethylbenzene’s impact is plain. Its main home is in resins, ion-exchange beads, and specialty polymers that underpin water treatment and chemical separation. The adjustable double bond means polymer scientists control flexibility or crosslinking density, unlocking everything from tough, shatterproof consumer goods to advanced filter membranes that survive decades of use. In adhesives and coatings, the chemical delivers both body and resistance, living up to its reputation among formulators who appreciate consistent batch results. Over recent years, the electronics industry has nudged into the mix, eyeing specialty polymers derived from vinylethylbenzene for dielectric and encapsulation roles.

Research labs worldwide dig deeper into what this compound can offer. Newer studies jump on sustainable routes: biocatalytic production, green solvents, or ways to cut down hazardous byproducts. More recently, development teams explore hybrid copolymers, using vinylethylbenzene to unlock a wider range of electrical, mechanical, or optical properties. Scientists are turning to advanced analytics, such as NMR and tandem mass spectrometry, to pin down microscopic performance, while pilot programs test these concepts outside controlled settings to ensure reproducibility at scale. Not all ideas make it past this stage; the ones that do help companies land next-generation materials with lower carbon footprints and higher lifecycle stability.

Nobody ignores the health angles. Toxicology teams map both acute and chronic exposure effects in mammals and aquatic species. Early animal tests showed mild skin and eye irritation, though longer studies found no significant carcinogenicity at realistic exposure levels. Inhalation at high concentrations triggers respiratory symptoms; workplace exposure controls built off this data have become part of the standard industrial hygiene toolkit. Environmental studies flag persistence as a growing issue—vinylethylbenzene, like many aromatics, can resist breakdown, urging ongoing work into bioremediation and waste stream preprocessing. Researchers monitor metabolites, study environmental transport, and publish guidance for safe limits. The latest trend runs toward more sensitive bioassays and realtime workplace monitoring, risk management shifting to fit better with new findings.

If past patterns hold, demand for vinylethylbenzene stands to climb as specialty plastics and green resin technologies expand. Markets worldwide push for lower toxicity, higher recycling rates, and smaller environmental footprints, nudging producers toward cleaner production lines and renewable feedstocks. R&D teams already weigh lifecycle impacts, balance performance against disposal issues, and hunt for catalysts that deliver more with less energy. Regulation also keeps up the pressure to drive down volatile organic emissions and minimize occupational exposure risk. As hybrid plastics roll out in consumer electronics, healthcare, and infrastructure, the need for tight control over monomer purity and isomer composition will only grow. Every new patent and R&D breakthrough prompts another review of how processes or formulations might step up. History suggests adaptability, careful control, and a willingness to rethink tradition will open the next chapter for this understated chemical player.

Vinylethylbenzene usually slips under the radar in daily conversation. It deserves some attention if you're curious about the chemistry behind modern products. Nobody comes across a bottle labeled “vinylethylbenzene” at the store, but this compound lies inside the manufacturing world of plastics, coatings, and even insulation. Think of it as a building block, quietly holding up bigger things we often take for granted.

Plastic has a big presence in today’s world. Vinylethylbenzene usually gets blended into polystyrene production, especially specialty grades known as “high impact” and “styrene-divinylbenzene copolymers.” That might sound technical, but the impact hits many homes—refrigerator linings, tackle boxes, and insulation panels all depend on materials like these.

Manufacturers love this ingredient because it can give finished plastics a bit more strength or resistance to heat than plain polystyrene offers. Workers in these factories watch the ratios, tweak recipes, and run tests to get a product that stands up to heavy use without cracking or falling apart. Vinyl and aromatic rings in the chemical structure help resist heat, so appliances and construction materials last longer.

There’s another side to vinylethylbenzene that shows up in water treatment plants. Some industrial filters use resins made from crosslinked styrene and vinylethylbenzene. Water percolates through, and those sticky resin beads catch unwanted impurities. Safe, clean water flows out the other side.

Drinking water doesn’t just show up tap-fresh by magic. I’ve watched plant operators pay close attention to the resin beads. They track performance and swap them when absorption drops off. Each batch gets tested for traces of unwanted compounds so everything stays above board and safe for communities.

Of course, everything in chemistry comes with questions. Most research so far finds that finished plastics made with vinylethylbenzene pose little threat to health when used as intended. But the chemical by itself can cause trouble if mishandled. Factories that process it follow strict ventilation and safety protocols—goggles, gloves, testing for air leaks. This stuff doesn’t play well with open flames or prolonged skin contact. I’ve seen veteran workers show rookies where the emergency showers and vents are before starting a shift.

On the environmental side, older plants needed to improve spill response and air emissions. Newer processes lean on closed systems and sensors to catch leaks early. There’s always debate about plastic waste, though. Even hearty foams and specialty cases eventually become trash. Some companies look for ways to recover or recycle used material, but options depend on local resources and the chemistry itself.

It’s easy to forget what goes into making a fridge lining tough enough to last through moving day or what’s sitting behind the drywall keeping a house warm. Vinylethylbenzene plays a role in making these products stronger and longer-lived. The next step for society might involve not just making sturdy stuff, but making sure it can be recycled or safely broken down once it reaches the end of its useful life. For now, understanding this kind of ingredient helps everyone make more informed choices—one bottle, one appliance, one decision at a time.

Factories and labs use Vinylethylbenzene, often as a building block for plastics and resins you’ll find in car parts, electronics, coatings, and sometimes even packaging. The chemical blends into consumer goods and workplace materials. Trouble pops up during production, transport, and disposal: people can come into contact with raw or spilled material, and workers especially encounter it straight from containers.

Several regulatory agencies point out the risks tied to Vinylethylbenzene. According to the European Chemicals Agency, the substance causes skin and eye irritation and may lead to allergic reactions after repeated exposure. The US National Library of Medicine shares similar warnings, highlighting headaches, dizziness, and respiratory discomfort after inhalation. If the material touches skin, it can trigger redness or rashes. Short-term symptoms can slide under the radar, so without proper protective gear, exposure at work or from a leak could go undetected at first.

Animal studies—still a big part of industrial safety research—show that high doses damage liver and nervous system tissues after long exposure. While actual environmental or consumer exposure sticks to much lower levels, chronic intake or poor ventilation could pile up the effects, especially in small spaces.

Vinylethylbenzene, at the concentrations found in workplaces, does not get labeled as acutely toxic for a single, brief encounter. It falls under the “hazardous chemical” label by OSHA and the ECHA, not because it kills outright, but because its effects add up with ongoing exposure. The chemical’s vapor can displace oxygen and ignite easily. Firefighters and spill-response teams actually worry more about explosions than short-term poisoning, though chronic health issues deserve real concern.

Toxicology data points to a need for strict ventilation rules and airtight storage. Protective gloves and goggles kept me and my coworkers safe during my past work in industrial quality labs. A co-worker once ignored his gloves, thinking a quick bottle change wouldn’t matter—he got a mild rash and a stern lesson from the shift supervisor.

Vinylethylbenzene’s ability to spread and vaporize pushes risk far beyond the person holding a drum. Airborne chemical release can drift into broader spaces in a factory or warehouse, especially if ventilation falls behind demand. Soil and water contamination does not follow the pattern of some pesticides, but chemical spills do leach small amounts into groundwater. Cleanup crews rely on absorbent pads and chemical neutralizers—good training pays off in these cases. Environmental monitoring programs help keep releases in check, and local residents deserve clear information whenever a spill occurs.

Practical steps come from years of incidents and regulation. Factories should fit strong local exhaust systems in mixing and bottling areas. Workers need to keep gloves, eye shields, and respirators handy. Clear labeling and quick spill control gear put safety into real action. For small businesses, supplier education helps when bigger manufacturers update their storage and safety sheets.

Hazardous by nature, Vinylethylbenzene reminds us that safer alternatives deserve investment and that risk doesn’t vanish just because a product seems invisible to the end user. People directly handling chemicals, and those living nearby, both count on vigilance and transparency backed by facts, not bland assurances.

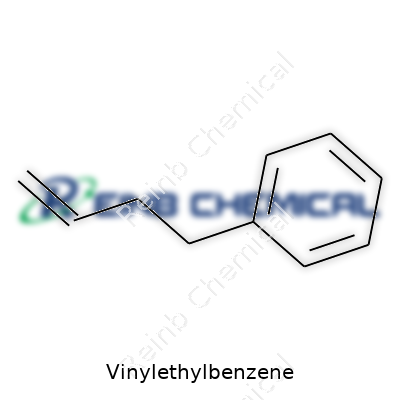

Vinylethylbenzene stands out in the world of organic chemistry for its basic but crucial structure. At its core, the molecule carries a benzene ring, which serves as one of the most familiar aromatic rings known by anyone who’s ever glanced at a high school chemistry textbook. Attached to this ring are two simple but important groups: a vinyl group (–CH=CH2) and an ethyl group (–CH2CH3). These groups sit at the 1 and 4 positions, making the most widely discussed isomer para-vinylethylbenzene.

Putting together vinyl and ethyl with benzene gives a backbone that’s easy to recognize. You get a six-carbon aromatic ring, which offers stability and resonance, and branching off you find the vinyl group, a two-carbon chain ending with a double bond, along with the ethyl side chain—the simplest little branch you’ve ever drawn in a notebook. Chemists see this kind of structure pop up in the lab because double bonds bring a certain reactivity: they want to react, want to bond with new things, and that’s at the heart of why compounds like this one matter.

Vinylethylbenzene earns attention because its structure gives it unique chemical properties. The vinyl group doesn’t just hang off the ring; it opens the door to all kinds of polymerization reactions. In industry, that vinyl group is valuable for creating polymers and plastics that see daily use. Polystyrene, a common plastic, arises from a similar cousin, styrene. Swapping just a hydrogen for an ethyl group changes reactivity and the physical feel of the resulting material. This small tweak changes how materials perform under stress, temperature, or exposure to chemicals.

My early research lab experiences brought me close to vinyl-containing aromatics. Their sharp smells and slick, oily texture stuck in memory as much as their role in reactions. Teaching undergrads how subtle changes to a molecule affect its behavior brings the importance of these structures to life. Sometimes, students ask why manufacturers chase after so many benzene derivatives. It’s because the foundation is proven, and minor tweaks fit products for everything from insulation foam to the casing around electronic parts.

Using compounds like vinylethylbenzene calls for careful consideration of safety and environmental impact. Benzene rings raise flags, as some related compounds may lead to health issues if handled carelessly. Safer handling routines, better ventilation, and strict exposure limits in workplaces go a long way in protecting those working with such chemicals. Researchers keep looking for greener production methods too—methods that create less waste, rely on renewable feedstocks, or reduce hazardous byproducts. Sometimes innovation grows from finding replacements for single groups on a familiar molecule.

Finding alternatives isn’t just about making something new for the sake of novelty. It’s about understanding the structure, predicting how a molecule acts, and balancing performance with safety. As more companies commit to sustainable production, molecular tweaks—like the difference between ethylbenzene and vinylethylbenzene—push research forward. That same structure, studied in college labs and used in vast industrial syntheses, holds the potential for future solutions in plastics, coatings, and specialty materials.

Vinylethylbenzene hardly shows up on most people’s radar, but for workers and businesses dealing with styrene and resins, it matters a lot. Unsafe handling or sloppy storage can ruin entire batches, spark regulatory fines, or create hazards no one wants to see. I’ve heard about small fires that got out of control because someone let a drum get too warm or left it near a spark source. No mystery here – this stuff can react if left unchecked. Keeping it safe means understanding what it’s like to work with chemicals that have well-documented dangers.

This isn’t the sort of chemical you want sitting outside on a summer day. Vinylethylbenzene breaks down and forms unwanted byproducts if the temperature climbs or drops beyond recommendations. Anyone who’s spent time in a warehouse during heatwaves knows how fast a cool space can turn into a sauna. The sweet spot for this chemical usually falls right below room temperature – think in the range of 15 to 25°C. Avoiding any direct sunlight or heat sources adds a crucial line of defense. Workers loading or unloading containers should keep them off hot surfaces or away from equipment that heats up. Reliable storage saves money because it cuts down on waste and keeps the material in spec.

Folks sometimes treat closed drums as if they’re invincible, but age and rough handling cause even good containers to leak. One neighbor I knew took short cuts with half-sealed barrels in a back storage shed, and it led to a clean-up crew spending hours in protective suits. Not only does the chemical smell linger, but improper storage can harm groundwater, soil, and even nearby buildings. No one wants a visit from environmental inspectors after a preventable accident either. Good storage means checking for rust, dents, or wear. Designated, clearly labeled shelves with tight-fit lids and secondary containment, such as spill trays, help everyone avoid real problems. Staff should grab gloves and goggles before even moving a container, since skin contact or inhaling fumes causes trouble fast.

The smell of vinylethylbenzene is hard to forget, and breathing it in over time puts workers at risk. Keeping storage rooms well-ventilated makes sure that small leaks don’t build up and create a bigger threat. Setting up rooms with fans or exhaust systems isn’t only for show – it’s the easiest way to avoid dizziness, headaches, or worse. I’ve learned tough lessons from properties where fire safety plans didn’t exist. With chemicals like these, all it takes is a spark, faulty wiring, or even static to start a disaster. Flame-retardant materials and no-smoking signs do more than satisfy the rulebook – they keep everyone going home healthy.

Most problems show up when staff don’t know better or forget small details. It’s not enough to have a dusty manual tucked away. The value comes from hands-on training and walkthroughs. Supervisors who review procedures and update everyone about new regulations make a big difference. Sharing stories about mishaps, near-misses, and fixes teaches more than written rules alone. In workplaces that keep training regular, accidents drop and crews feel more confident dealing with tough stuff like vinylethylbenzene.

Smart storage for this chemical keeps people safe, protects the environment, and preserves business assets. There’s no shortcut to doing it right – just solid practices built on real experience and respect for how quickly things can go wrong.

Vinylethylbenzene pops up in plenty of labs, especially in polymer chemistry and the manufacturing of resins. Few outside those circles recognize the name, but anyone working near this stuff knows its strong, unmistakable odor enough to step back and check their gear twice. Handling aromatic hydrocarbons like this one means staying on the right side of common sense and real experience.

I once worked on a research team where shortcuts didn’t get a pass—especially after a single whiff of mishap shut down a whole project for days. A minor spill in an unventilated room sent two colleagues running for fresh air, coughing hard and suffering headaches the rest of the day. One had skipped goggles, thinking “my glasses are enough.” That gamble didn’t pay off.

Goggles aren’t optional. Neither are long sleeves and lab coats. Vinylethylbenzene can irritate skin and eyes, and no one looks smart hustling to an eyewash station. Splash-resistant gloves matter as well, with nitrile or neoprene working better than latex. Nobody wants to test every warning the hard way.

Oversights cost real comfort. This chemical evaporates easily, and inhaling its vapors brings headaches, dizziness, even worse with steady exposure. Good ventilation, preferably with fume hoods or exhaust fans, drops those risks fast. HVAC systems alone can’t keep up. The difference between stuffy air and clean air after opening a container leaves a mark you don’t forget.

Early in my career, a poorly sealed container of vinylethylbenzene leaked into a storage drawer. We found out only after catching a strong whiff during inventory. Seals matter almost as much as the labels on bottles. Store the chemical in cool, dry places, away from sparks, flames, or sunlight—vinylethylbenzene can flash up at temperatures most warehouse workers consider normal. Flammable liquids belong in fireproof cabinets, not on open shelves.

Material Safety Data Sheets point out the risks: eye and skin irritation, flammability, and the dangers of breathing in too much. Those aren’t just box-check warnings. Close calls show that simple mistakes—leaving the cap loose, skipping gloves, or ignoring a hood alarm—stack up over time. Physical symptoms don’t always show right away, but headaches and nausea creep in, sometimes hours later.

Safety culture picks up speed once workers see their own team take rules seriously. It helps to keep spill kits within arm’s reach—absorbent materials, neutralizers, and the right disposal bags make a difference. Training for new workers can’t stop at videos; supervisors and veteran lab techs should walk through actual cleanup drills and real examples. Immediate reporting of leaks or symptoms lets others learn vicariously, instead of the hard way. Fitting proper signage near storage areas keeps newcomers from learning the wrong lessons first.

Over time, respect for chemicals like vinylethylbenzene comes from small routines—checking gloves, snapping lids shut, opening windows, double-checking labels. These steps become habits, not chores, carrying over from work into other parts of life. Each person’s vigilance multiplies behind the scenes, making sure both old hands and newcomers stick around healthy and sharp for a long time.

| Names | |

| Preferred IUPAC name | 1-Ethenyl-4-ethylbenzene |

| Other names |

4-Ethenyl-1-ethylbenzene 4-Ethylstyrene v-Ethylstyrene |

| Pronunciation | /ˌvaɪ.nəlˌiː.θəlˈbɛn.ziːn/ |

| Identifiers | |

| CAS Number | 100-63-0 |

| Beilstein Reference | 2781250 |

| ChEBI | CHEBI:52205 |

| ChEMBL | CHEMBL16262 |

| ChemSpider | 14220 |

| DrugBank | DB14510 |

| ECHA InfoCard | 03b6e0e6-fc45-4cfb-ba3d-3b969d6cf0a8 |

| EC Number | 214-452-7 |

| Gmelin Reference | 71572 |

| KEGG | C14379 |

| MeSH | D014738 |

| PubChem CID | 7500 |

| RTECS number | WJ8925000 |

| UNII | 4EA3D33V27 |

| UN number | UN2618 |

| Properties | |

| Chemical formula | C10H12 |

| Molar mass | 132.20 g/mol |

| Appearance | Colorless liquid |

| Odor | aromatic |

| Density | 0.909 g/mL at 25 °C(lit.) |

| Solubility in water | Insoluble |

| log P | 3.7 |

| Vapor pressure | 0.38 mmHg (25°C) |

| Acidity (pKa) | 40.53 |

| Basicity (pKb) | 8.8 |

| Magnetic susceptibility (χ) | -7.58e-6 cm³/mol |

| Refractive index (nD) | 1.5460 |

| Viscosity | 1.670 mPa·s (25 °C) |

| Dipole moment | 0.72 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 354.9 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | 89.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4977 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H315, H319, H335 |

| Precautionary statements | P210, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 2-3-2 |

| Flash point | 68 °C |

| Autoignition temperature | 490 °C (914 °F) |

| Explosive limits | 1.1–6.4% |

| Lethal dose or concentration | LD50 (oral, rat): 3160 mg/kg |

| LD50 (median dose) | Rat oral LD50: 3160 mg/kg |

| NIOSH | GV0825000 |

| PEL (Permissible) | 100 ppm (OSHA) |

| REL (Recommended) | REL (Recommended): 10 ppm (50 mg/m3) |

| IDLH (Immediate danger) | 1000 ppm |

| Related compounds | |

| Related compounds |

Ethylbenzene Styrene Divinylbenzene |