Chemistry keeps turning out compounds that shape everyday goods, and zinc 2-ethylhexanoate is one of those trailblazers, especially for coatings and plastics. In the 1960s, industries chased more stable, reliable metallic soaps to keep up with new demands in automotive finishes and PVC stabilization. Labs and factories pushed zinc 2-ethylhexanoate into wider use because it lined up just right with evolving needs. Instead of relying only on centuries-old lead-related stabilizers, folks developed zinc carboxylates for safety and performance. As the coatings industry shifted away from heavy metals, this chemical gained ground, getting baked into primers, varnishes, and flexible plastics, with research spreading from Europe to North America and then out to Asia as manufacturing scaled up.

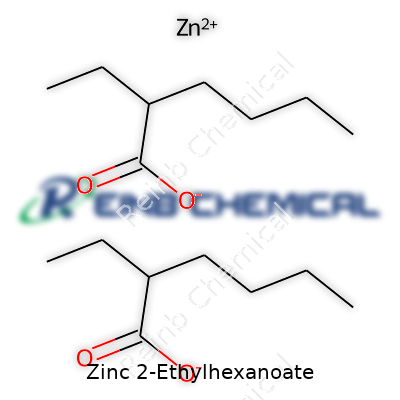

You can find zinc 2-ethylhexanoate in liquid or sometimes pasty form. Its main ingredient, zinc, gets combined with 2-ethylhexanoic acid, a synthetic fatty acid that’s tougher and more stable than animal products. Zinc 2-ethylhexanoate flows into paint dryers, stabilizers for vinyl, catalysts for polyester, and more. Coating makers keep it in their inventory for fast drying; plastic manufacturers rely on it for less yellowing and better weather resistance. Polyurethane makers prize its ability to help kickstart reactions without unwanted byproducts, giving them cleaner foam and elastomers.

This compound’s physical profile usually includes a pale, yellowish liquid, a faint but characteristic odor, and moderate oiliness. In my experience, it resists breaking down under raised temperatures—good news for heated manufacturing processes. Zinc 2-ethylhexanoate dissolves in oils and organic solvents but stays clear of water and harsh acids. Its molecular structure keeps it stable, so it stores for months in sealed drums and pours easily for dosing. Zinc content lands around 8–12% by weight, which gets double-checked with each new drum that hits the production floor.

Manufacturers stamp clear labels on drums, marking CAS numbers, zinc concentration, solvent balance, and safety directions. Labels usually lay out lot numbers for traceability. Color and viscosity codes line up with batch expectations, avoiding surprises during mixing. I’ve noticed handlers insist on checking SDS sheets before the first shipment arrives, preparing for spills or splashes. Companies track purity: zinc 2-ethylhexanoate with too much free acid gums up machines or leaves coatings tacky. Reputable suppliers send certificates of analysis with each delivery so buyers can keep specs on track.

Factories synthesize zinc 2-ethylhexanoate through direct reaction between zinc oxide and 2-ethylhexanoic acid, cooking them at controlled temperatures in stainless-steel reactors. Operators stir the mix under nitrogen atmospheres to tamp down oxidation, then filter the product for clarity. Excess acid or water gets stripped out by heating under vacuum, which is important for batch consistency. Old-style processes added amine bases as catalysts, but newer methods reduce those additives, aiming for straightforward chemistry and fewer byproducts. Each batch starts with careful weighing: too much zinc oxide fouls up viscosity, while too much acid leaves you with a product that eats through valves.

Chemists treat zinc 2-ethylhexanoate as a versatile building block. It reacts with atmospheric moisture, forming a thin zinc soap layer if exposed to air too long during transfers. In coatings, it acts as a drier, sparking crosslinking in alkyds and speeding up cures. Folks working in polyurethane tweak the blend, mixing zinc 2-ethylhexanoate with other metal carboxylates to craft custom catalyst packages. I’ve seen research labs test modified versions with branched acid tails, shifting drying speeds and compatibility with newer solvents. It takes heat well, but overcooking breaks it down into volatile organic acids, so operators watch temperatures closely.

The chemical pops up under several aliases in trade catalogs: zinc octoate and zinc 2-ethylcaproate rank as common alternatives. Some suppliers name blends using their own trade brands, such as Octoate ZN-8 or Drier ZN-12, depending on zinc percentage or solvent carrier. I’ve flipped through technical datasheets that lump it under “metal carboxylates” or “zinc soaps,” which sometimes confuses first-time buyers. It’s important to match the CAS number (136-53-8) and zinc weight to ensure you get the right grade for your process.

Handling zinc 2-ethylhexanoate needs respect for skin and eye contact. Though not as nasty as lead soaps, it irritates on contact and demands gloves, goggles, and proper ventilation. Factory floors stash neutralizing agents and absorbent pads for spills, and operations train handlers to clean up without spreading the material. Airborne exposure standards get checked with regular monitoring; engineers design storage tanks with sealed lids to hold in vapors. Disposal calls for licensed chemical waste handlers—nobody dumps this down the drain. Regulatory standards in Europe, North America, and East Asia require Material Safety Data Sheets and precise labeling before transport.

Most zinc 2-ethylhexanoate ends up in paint and varnish lines. In these formulations, it zips along oxidation and curing, making alkyd finishes dry fast enough for commercial deadlines. PVC stabilizer producers value its clean profile, avoiding yellowing in white or clear products. Polyurethane and polyester resin plants rely on the catalyst role in shaping foams, films, and adhesives. Even rubber production uses the chemical to promote crosslinking at lower temperatures, boosting consistency from batch to batch. In my experience, companies appreciate how small tweaks in dosage swing performance, so they run pilot batches before launching full production.

Lab teams keep returning to zinc 2-ethylhexanoate, hoping to minimize toxicity, improve eco-profile, or fine-tune performance. Environmental rules prompt researchers to cut down on volatile solvent content or replace petroleum carriers with sustainable alternatives. Specialty resin developers experiment with “green” versions—sometimes swapping to bio-based 2-ethylhexanoic acid or using micro-encapsulation to handle dosing safely. Recent projects test nanoscale dispersions, especially for waterborne paint systems. Journals and patent filings from the past five years show growing interest in hybrid catalysts, mixing zinc 2-ethylhexanoate with tin, cobalt, or manganese derivatives for broader application.

Studies generally point to low acute toxicity for zinc 2-ethylhexanoate, especially compared to legacy metal stabilizers like lead and cadmium. Still, toxicologists urge caution: zinc compounds in large doses upset aquatic life and build up in wastewater if not managed properly. Research shows chronic skin exposure can trigger irritation or mild dermatitis. In my own work, I’ve seen companies underline the need for closed systems and regular health checks, cut down employee exposure, and install respiratory filters in decanting areas. Biodegradation tests remain ongoing, especially in regions committed to zero-discharge policies, but so far the compound hasn’t flagged big red alerts in environmental monitoring.

As markets demand cleaner chemicals, zinc 2-ethylhexanoate’s prospects shift with new regulations and industry priorities. Paint formulators now want driers that work fast but with less smell and zero hazardous byproducts; plastic manufacturers look for alternatives that won’t disrupt their complex supply chains or create extra headaches at the end of product life. Research suggests new “hybrid” stabilization systems, pairing zinc with rare earths or organic metal chelates to extend durability or cut drying times further. Some experts bet on bio-based feedstocks and recycled solvent streams to shrink the chemical’s carbon footprint. Demand for reliable, safer metal catalysts keeps zinc 2-ethylhexanoate on the table, even as government standards push for higher traceability and more transparent testing.

Zinc 2-ethylhexanoate brings a lot to industrial production, but most folks never hear about it, even if they run across its handiwork every day. You’ll likely find it on the ingredient list of many coatings, paints, and even plastics. This stuff comes in handy in places where fast and thorough drying is important. It’s not glamorous work, but it's the kind of background support factories depend on for getting a good finish and moving a product from one step to the next.

Drying time makes a big difference in paint, especially for anyone who's worked with big projects or tight deadlines. Zinc 2-ethylhexanoate acts as a drier, speeding up the process and making the coating harden well. When painters want a steady, tough finish that stands up to weather, the right metal drier matters. Lead-based compounds once held this job, but health concerns moved the industry toward safer options. Zinc-based components stepped up, and you see that reflected in product lines across major paint manufacturers. Consumers want reliability and safety, and this compound helps make both routine.

In plastics, especially polyvinyl chloride (PVC), stabilizers hold everything together under heat and exposure over time. Factories depend on zinc 2-ethylhexanoate because it helps keep the color and structural strength of the material. Heat easily degrades plastics, but certain additives slow that down. Zinc 2-ethylhexanoate helps prevent damage and discoloration, so windows, pipes, and vinyl remain strong after production and during use. Less breakdown means longer life and less waste, which makes a difference on any job site.

Health and safety matter, especially as more evidence shows how long-term exposure to old-school chemicals hurts both people and planet. Industries using zinc-based driers and stabilizers give themselves an edge by moving away from toxic metals. The cleaner the chemistry, the easier it becomes to meet tighter rules and reassure customers about what goes into common household items. My own work in construction showed me how clients often ask about everything going into their remodels. Transparency builds trust, and products using this kind of safer additive usually have an easier time finding a market.

No additive escapes scrutiny when it comes time to recycle or dispose of materials. While it’s safer than some older options, regulatory agencies and recyclers keep tracking where and how zinc compounds show up. Waste management remains an issue, especially with complex plastics. Better labeling and clearer documentation at every stage in supply chains make a big difference. Pushing for more recycling-friendly formulations supports the shift to sustainable industry.

Safer, high-performing additives only do their job well if handled right. Worker education matters, especially for those at the mixing and application stages. Customers should know what’s coming into their homes or cars. Producers can strengthen their businesses by staying honest and seeking out the most up-to-date, responsible technology. Safer chemistry builds trust, and over time, the extra effort leads to stronger communities and better products on the shelf.

A lot of work in paint, coatings, plastics, and the world of specialty chemicals leans on quality raw materials. Zinc 2-ethylhexanoate stands out as a common zinc source, especially valued as a curing agent and catalyst. Purity drives trust and performance, so knowing what goes into each drum really matters.

Over the years, my dealings with chemical supply have revolved around chasing specifications—not just for compliance but for repeatable outcomes. Impurities in catalysts or additives might sound minor on paper. They can show up as yellowing in coatings, unpredictable curing, or wasted resin. Downstream customers turn a magnifying glass on these details. Even a fractional shift in metal content or unexpected residue creates new headaches during QA testing.

Commercial Zinc 2-ethylhexanoate typically clocks in at around 8% to 12% zinc metal content. Most drum labels quote this "as zinc" figure, since formulations revolve around how much active zinc makes it into a finished mix. In practice, big suppliers stick with controlled batches that test between 8% and 10% zinc, with lower levels appearing rare and higher ones carrying a price uptick.

The carrier—2-ethylhexanoic acid and its byproducts—doesn't play a starring role; most users scour certificates of analysis for metals, moisture, and organic residue. Too much free acid hints at incomplete reaction, which could mess with curing. Too little total zinc means fewer active sites and weaker results. Lab tests can pick up even small shortfalls.

I recall clients mixing pilot batches only to end up with sticky, half-cured sheets. Eventually, someone traced the culprit to a low zinc content that had crept below 7.5%. Turns out, inconsistent purification or filtration let things slip by. This taught the value of steady sourcing.

Reliability doesn’t stop at purity numbers. Trace metals like iron, copper, or lead can sabotage performance. Regular ICP or AAS testing helps keep tabs on contamination. Some markets demand “high-purity” grades, where zinc exceeds 10% with almost zero detectable impurities, supporting electronics or medical-grade plastics. Paints, by contrast, usually run with standard spec (8-10%).

Chemistry isn’t all about reacting compounds; it’s about listening to what frontline operators say. Issues around purity usually trace back to missed checks or communication gaps between supplier and customer. Cutting corners seldom pays off—one bad shipment means rework, disposal costs, or losing contracts. Detailed specifications up front, regular batch testing, and transparent certificates help head off disputes.

Digital tracking and automated dosing systems are reshaping how companies assure consistency. Barcode scans now speed up receiving, and batch software flags inconsistencies before production scales up. Industrial end users increasingly expect QR-enabled traceability. Knowing the purity of what you’re running—down to the decimal—shaves off worry and waste. It’s hard to beat the value of clear standards and open recordkeeping in the world of zinc chemistry.

Zinc 2-ethylhexanoate pops up in a surprising number of places. You see it in paints, coatings, plastics, and rubber manufacturing. Chemists hold onto this compound for its use as a catalyst or paint drier. It gets the job done and keeps things moving on factory floors.

Folks sometimes ask: Do I need to worry about this chemical? It feels wise to take a closer look, especially if your job has you working around it all day. Straight to the facts: zinc 2-ethylhexanoate doesn’t show the sort of severe hazards you find in strong acids or volatile solvents, yet no one should toss caution out the window.

Safety data sheets flag it as an irritant. If the substance touches skin or the eyes, you can expect burning, redness, or itching. There's a reasonable chance you'll want to wash up quick if you get some on your hands. Inhaling the vapor or mist stirs up nose and throat irritation, coughing, or headaches. Swallowing it means a trip to a doctor, fast.

No official occupational exposure limit exists for zinc 2-ethylhexanoate in many countries. Still, workers don’t get a free pass to ignore risk. Facilities using this chemical tend to treat it like other organic metal salts. Think gloves, goggles, lab coats, and solid ventilation or a fume hood. Respirators may join the gear list during spills or with poor airflow.

Controlling dust or aerosols usually ranks high on the list of best practices. You notice the safety habits in long-running factories: handwashing stations, clear labeling, emergency eyewash units. These routines keep minor exposures from turning into worker injuries or lost time.

Looking at the bigger picture, chronic exposure brings up new concerns. Studies don’t pile up for zinc 2-ethylhexanoate the way they do for more notorious chemicals, but skin contact can cause dermatitis for sensitive folks. No concrete evidence links it to cancer or genetic problems as of now, based on available toxicology data. The science here doesn’t mean unlimited use is wise — more like a reason to take good habits seriously and limit exposure.

A spill or improper disposal should get handled right away. Zinc compounds can stress aquatic life if they escape into water. Companies owe it to workers and the environment to obey disposal regulations, seal containers tightly, and train teams for emergencies.

What stands out from working around this substance is the value of treating chemicals with respect. Even when labels say “low hazard,” nothing replaces personal protective equipment and a habit of reading up before pouring or mixing. Training pays off here — it gives workers a voice, encourages quick reporting of exposure, and helps people spot unsafe storage in time.

By leaning into strong safety routines, both seasoned workers and new hires build a culture that catches mistakes before they hurt anyone. I’ve seen places with zero incidents for years — not because their chemicals lack hazards, but because the people didn't cut corners or ignore safety sheets. Knowing the risks, staying prepared, and pushing for clear policies make all the difference.

Anyone who's handled chemical additives in an industrial setting soon learns that storage often makes all the difference between smooth operation and surprise downtime. Zinc 2-Ethylhexanoate, often used as a drier or catalyst in coatings and plastics, behaves like many other zinc salts: not exactly hazardous waste, but far from ordinary household goods. The bottle’s label may warn about irritation and flammability, but it won’t teach you why the rules actually matter.

Storing chemicals near heat sources or in sunlight seems harmless after a busy day, but this easy habit can cause headaches down the line. Zinc 2-Ethylhexanoate, like many organometallics, doesn’t respond well to temperature swings. I once worked in a shop where a guy thought he’d keep his driers right by the paint oven for convenience—he learned quick those catalysts degrade faster, leading to inconsistent results on big production runs. It’s not just wasteful, it’s expensive.

Open containers or loose caps seem innocent. Yet this chemical can absorb moisture from the air which may affect its performance. In the worst cases, moisture brings clumping, changes in color, and even separation. You open the drum weeks later and find a gunky mess, or worse, the drier refuses to do its job in the mix. When products end up different each batch, managers look not at the supplier, but at how those chemicals were stored on site.

Oxygen matters too. Oxidation slowly kicks in, dulling performance and, sometimes, producing by-products. I’ve watched teams try to save cash by topping up half-empty containers, only to find out that the leftover air does more harm than good. Full, tightly sealed containers last longer and mean fewer quality headaches.

Plastic pails or steel drums lined for chemical resistance keep things safe and easy. Sizable labels, large enough to spot at a distance, end needless guessing each time someone grabs a container in the supply room. No shop supervisor likes cleaning up after a junior tech put the wrong additive in the wrong drum—clear storage rules and bright labels save both face and money.

Though not outright explosive, this zinc compound can feed a fire. Stacking containers away from open flames, direct heat, or sparking equipment seems obvious, but fire marshals write up facilities every week for failing at this one simple rule. A spill kit, sand, and clear instructions pinned to the wall do more to protect your people than any certificate. Every staffer should know accidental mixing with oxidizers or acids carries genuine danger.

OSHA and EPA guidelines set clear lines for how chemicals like Zinc 2-Ethylhexanoate get handled, stored, and disposed. Violations cost more than fines—they hit a business’s reputation. Routine training and monthly checks pull everyone into the safety process, closing the gaps that lead to spills, waste, or failed audits.

Storage rooms run cool and dry, with exhaust fans for any unexpected vapor leaks. New shipments get checked in, labeled, and logged. FIFO (first-in, first-out) means nothing sits unused so long it turns bad. Busy shops keep secure shelves and lockable cabinets away from foot traffic so the barrels stay upright and outside of accident-prone zones. A culture of care, where anyone can report problems and get real help, does more to protect quality and safety than any lock or sign alone.

Zinc 2-ethylhexanoate isn’t a household name, but its fingerprints show up in more places than folks might expect. This compound gets its main reputation as a specialty additive, but the scale and reach go far beyond trend or hype. I’ve seen it pop up every time I’ve helped someone troubleshoot paint issues or dig into the recipe for a heat-resistant coating.

Walk into any hardware store, and you’ll find paints promising faster drying or tougher finishes. Many of those rely on driers—a group of chemical additives that speed up the set time of alkyd-based paints. Zinc 2-ethylhexanoate falls in this group. Its role isn’t just to make things dry quicker; it helps avoid that yellowish tint other metal driers sometimes leave behind and keeps the paint film flexible. Because of rising regulatory pressure on lead and cobalt additives, more companies have leaned on zinc driers to get similar performance without health risks. Lead still floats around in old product lines, but zinc has proven a healthier and almost effortless switch in alkyd and industrial paint formulas.

Rubber stays resilient on car tires, conveyor belts, and shoe soles partly because of metal soaps. Zinc 2-ethylhexanoate plays referee between polymers and fillers during the vulcanization process. The compound steps in to help disperse active agents. Materials cured with this prompt stronger bonds and a nice resistance to cracking, even after months under pressure or heat. My mechanic neighbor said they’ve noticed longer-lasting rubber seals since manufacturers adopted these zinc compounds over older catalysts.

Plasticizers want to keep PVC soft. Stabilizers want to keep it from breaking down in sunlight or under heat. Zinc 2-ethylhexanoate fits into both camps. It acts as a co-stabilizer or a lubricant, depending on the recipe. Cables, flooring, and synthetic leathers hold up against sunlight and remain more supple when this sort of zinc additive is present. Fewer brittle cracks over time means less replacement and fewer tears landing in landfills, which environmental groups have been flagging for years.

Zinc 2-ethylhexanoate shows up behind the scenes in some less obvious places, too. In industrial lubricants, it helps keep metalworking fluids stable, especially under high friction. Oil refineries and power plants benefit from these stable lubricants. I’ve also read technical reports where this compound appears in wood preservatives and adhesives, shrinking the risk of rot and glue failures in challenging environments.

Cosmetics manufacturers sometimes turn to zinc-based soaps for dispersing colors or managing texture. Brands steering clear of parabens and other harsh chemicals found a decent middle ground by using compounds like zinc 2-ethylhexanoate. I noticed an uptick in zinc content listed on product ingredient lists, particularly among eco-friendly companies.

Every application faces the question: how much is enough and what’s the long-term effect? With more attention on sustainability, researchers push for alternatives with lower toxicity and less environmental impact. Recent studies from regulatory agencies nudge companies to measure runoff and worker exposure, not just product performance. I’ve seen industry groups band together for better guidelines and more transparent supply chains, aiming to strike a balance between stability, cost, and health safety. Chemistry won’t solve every problem overnight, but zinc compounds like this keep plenty of industries rolling forward and push product development into smarter territory.

| Names | |

| Preferred IUPAC name | Zinc bis(2-ethylhexanoate) |

| Other names |

Zinc bis(2-ethylhexanoate) Zinc octoate Zinc 2-ethylcaproate Zinc(II) 2-ethylhexanoate |

| Pronunciation | /ˈzɪŋk tuː ˌiːθɪlˈhɛksəˌneɪt/ |

| Identifiers | |

| CAS Number | 136-53-8 |

| Beilstein Reference | 1520495 |

| ChEBI | CHEBI:84955 |

| ChEMBL | CHEMBL612372 |

| ChemSpider | 5265717 |

| DrugBank | DB11106 |

| ECHA InfoCard | 03-2119475500-54-0000 |

| EC Number | EC 245-018-1 |

| Gmelin Reference | 87848 |

| KEGG | C20812 |

| MeSH | D015928 |

| PubChem CID | 23686605 |

| RTECS number | ZG8000000 |

| UNII | R10N1ZP9BC |

| UN number | UN3082 |

| Properties | |

| Chemical formula | C16H30O4Zn |

| Molar mass | 498.3 g/mol |

| Appearance | Clear, colorless to pale yellow liquid |

| Odor | Characteristic |

| Density | 1.14 g/cm3 |

| Solubility in water | Insoluble |

| log P | Log P: 4.7 |

| Vapor pressure | <0.01 mmHg (20°C) |

| Acidity (pKa) | pKa ≈ 4.86 |

| Basicity (pKb) | 6.23 |

| Magnetic susceptibility (χ) | -22.0e-6 cm³/mol |

| Refractive index (nD) | 1.493 |

| Viscosity | Viscous liquid |

| Dipole moment | 2.81 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 605.2 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -611.5 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4476.65 kJ/mol |

| Pharmacology | |

| ATC code | J01XX21 |

| Hazards | |

| Main hazards | May cause an allergic skin reaction. Causes serious eye irritation. Toxic to aquatic life with long lasting effects. |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H315: Causes skin irritation. H319: Causes serious eye irritation. H335: May cause respiratory irritation. |

| Precautionary statements | P210, P261, P280, P305+P351+P338, P370+P378 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | > 212 °C |

| Lethal dose or concentration | LD50 Oral Rat: 3,000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Rat oral 3,060 mg/kg |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Zinc 2-Ethylhexanoate: Not established |

| REL (Recommended) | 0.03-0.10 |

| Related compounds | |

| Related compounds |

Zinc stearate Zinc acetate Zinc octoate Zinc neodecanoate Zinc naphthenate Zinc laurate Zinc palmitate |